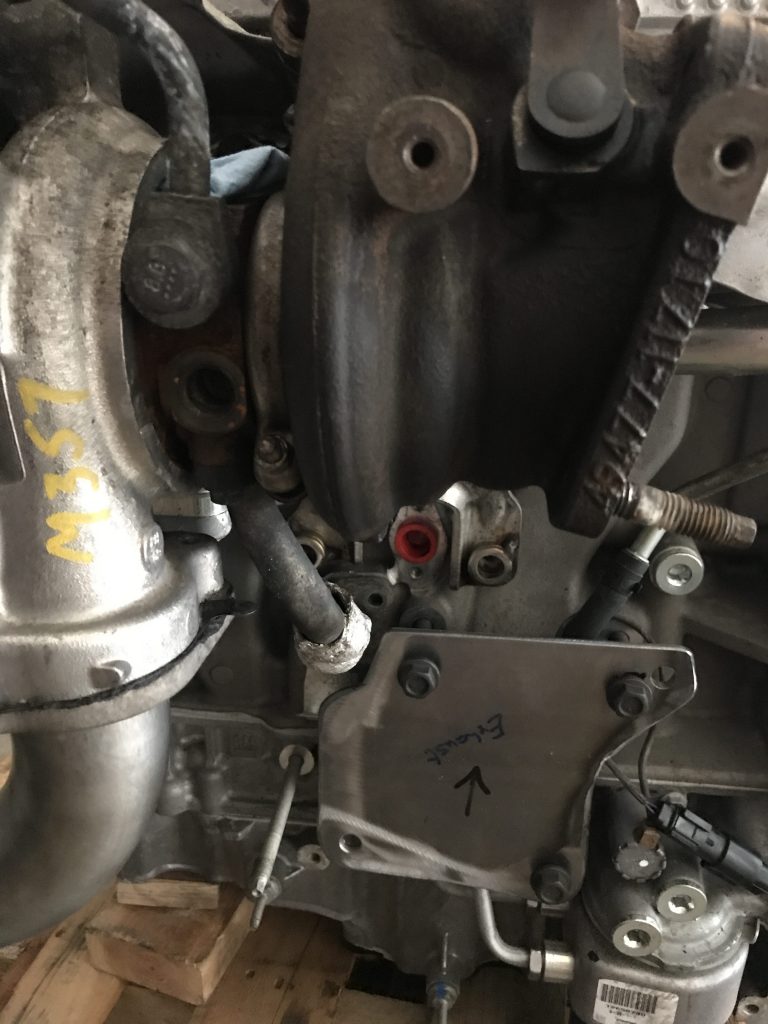

The hardest to find parts is anything related to the manual transmission. It’s really like looking for a needle in a haystack.

The hardest to find parts is anything related to the manual transmission. It’s really like looking for a needle in a haystack.

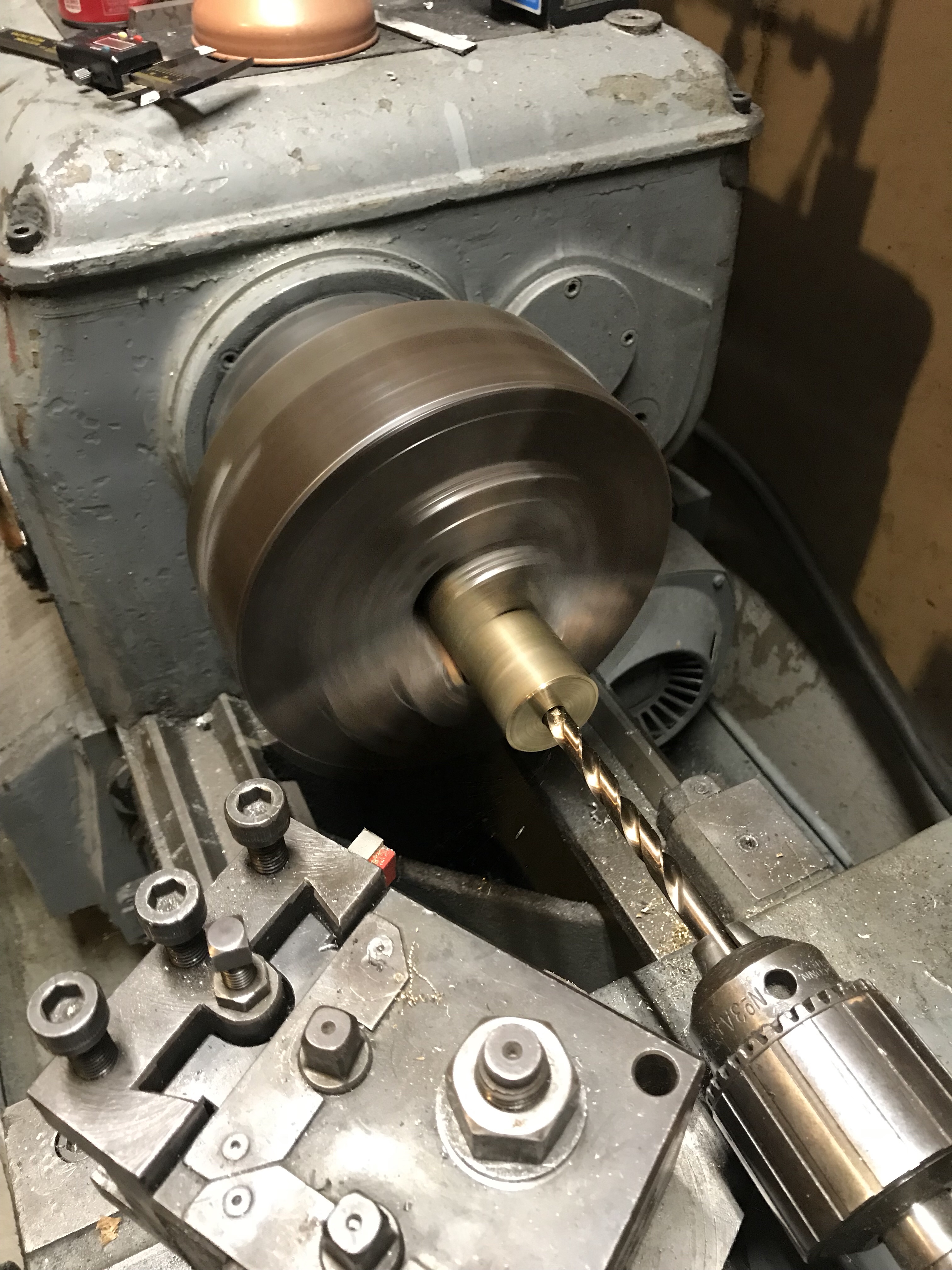

I bought a fidanza flywheel after refusing to pay $800+ for a factory flywheel. My entire life I have wanted a lightened flywheel so it was an attractive option.

The problems..

Firstly the flywheel bolts are custom. Thankfully Tim at Zzperformance hooked me up. I will admit that looking for M11 bolts was a pain in the ass!

Secondly the pilot bearing is a big question mark. It doesn’t look like the factory would fit and there isn’t much information about what to do. More to come on that front after I talk to Fidanza.

Lastly I have called a few dealers trying to find a factory clutch and pressure plate. Many of them don’t see it in the parts catalog which is frustrating. I will most likely just buy it from Zzperformance.

If you decide to go LTG I would recommend just buying the clutch masters at from zz and be done. Spending hours trying to find information for simple things is not worth the savings!

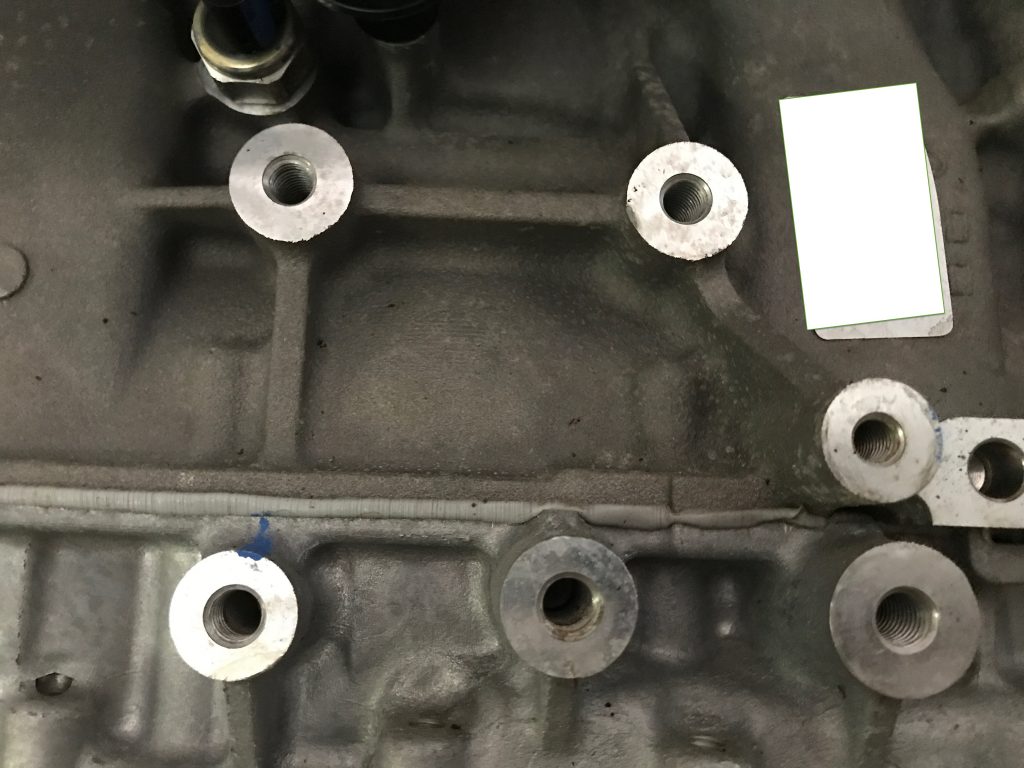

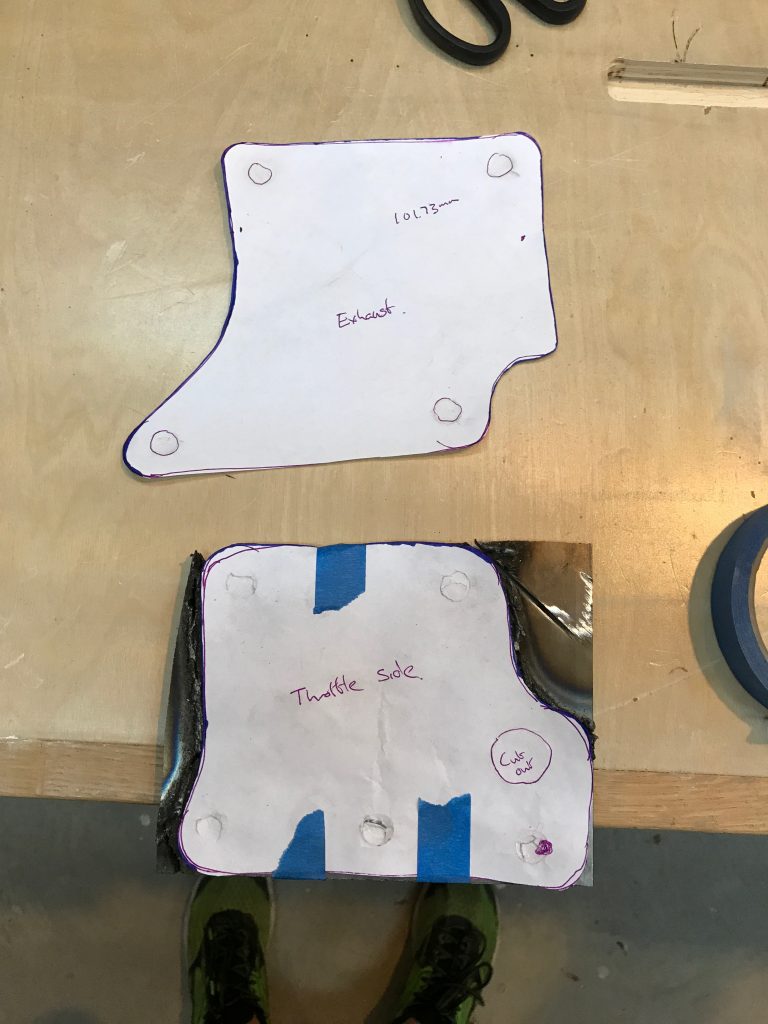

This is what I suspect the mounting plates will look like.

This is what I suspect the mounting plates will look like.

The hardest to find parts is anything related to the manual transmission. It’s really like looking for a needle in a haystack.

The hardest to find parts is anything related to the manual transmission. It’s really like looking for a needle in a haystack.