What started as a promising morning didn’t end very well. I pulled the motor mounts off of the engine and welded on the needed offset pieces. Things were going very well! (note the metal braces going forward is to prevent the engine from rocking)

Using the”custom bolts” needed for the flywheel I managed to get all 8 in place and hand tight. I’ll admit I don’t love that there is no locating pin on the flywheel because it allows all of the rotational torque to be transmitted through the bolts to the transmission.

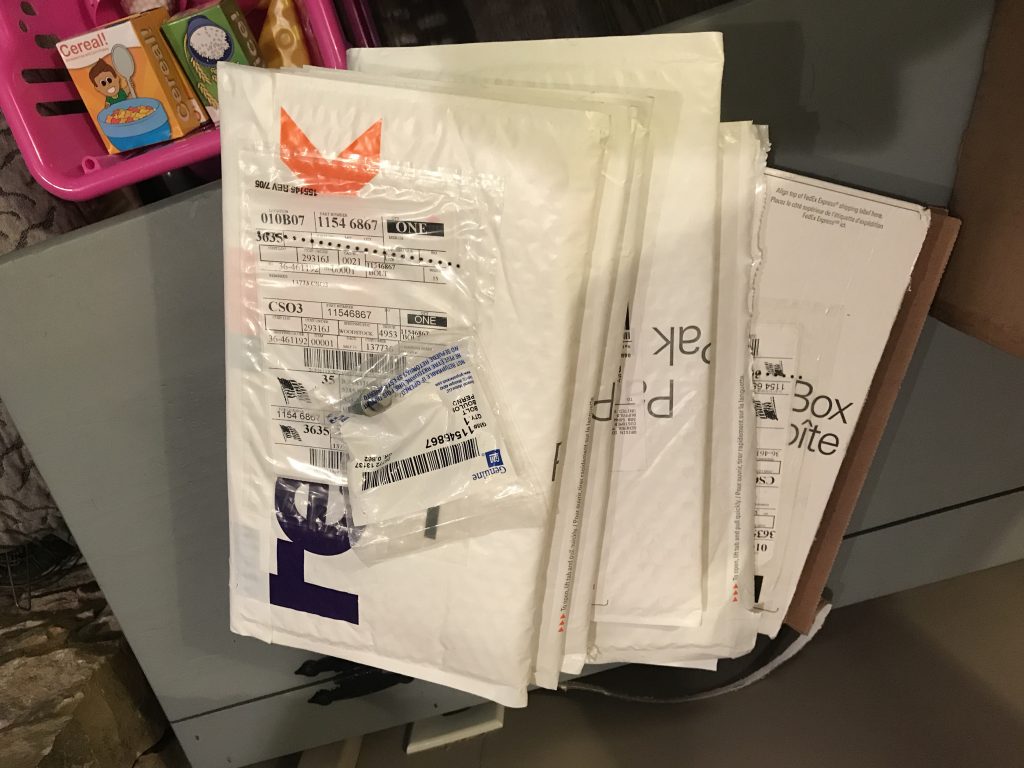

This is what the bolt looks like. It’s an m11 -which isn’t something you can easily find and definitely not something Chevrolet dealers usually stock.

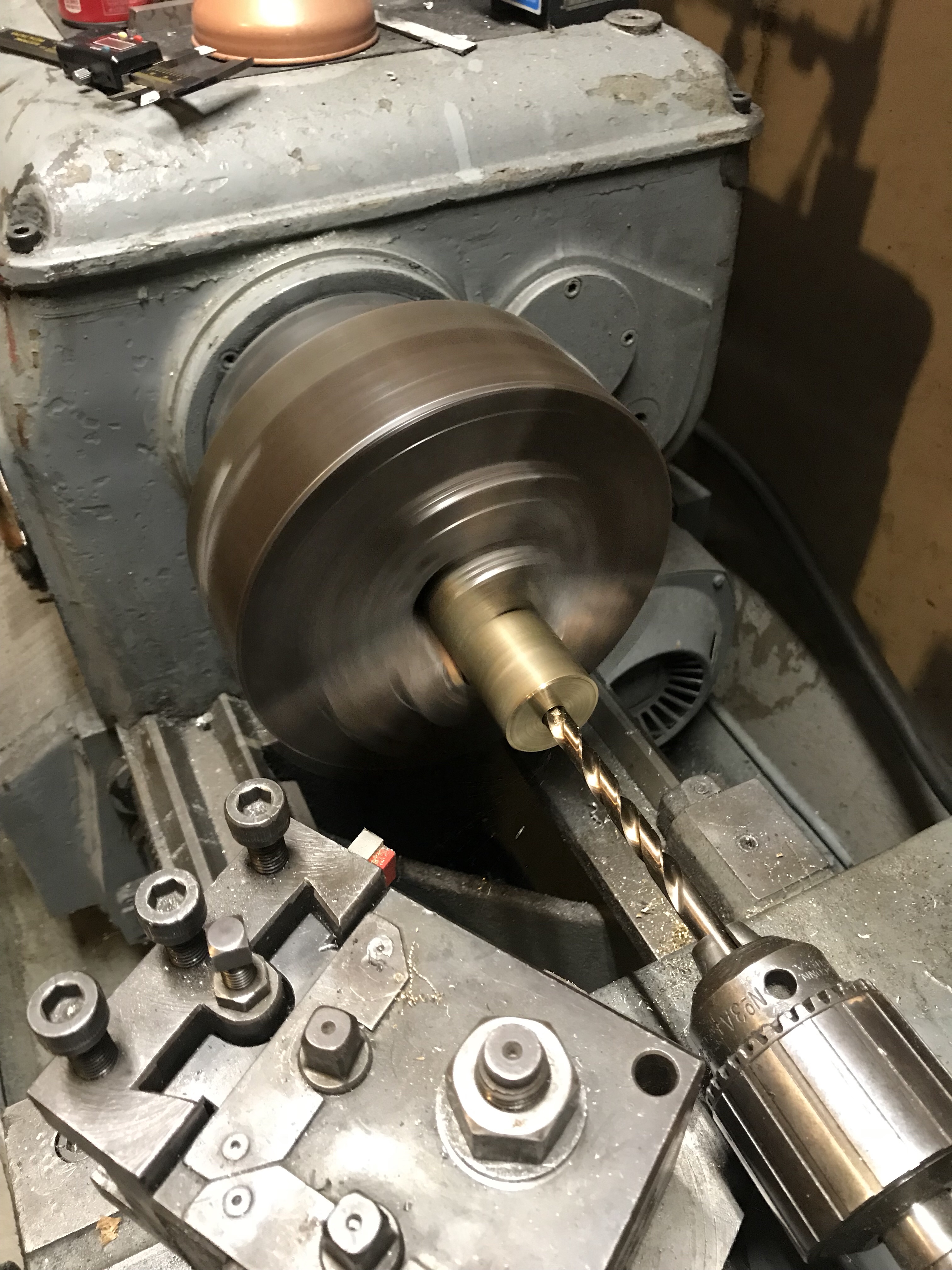

After hand tightening the bolts I grabbed the torque wrench and set to 20ft lbs I wanted to get everything started and check alignment.

The first bolt achieved 20lb fts but the next 2 appeared to strip out. At this point I stopped and removed all 8 bolts and inspected the damage.

Even though the bolts appear hardened they lost their threads quite easily. The crank was inspected and it is fine.

While not ideal I’ll give a few vendors a call on Monday and try sort it out. Unfortunately m11 is a very uncommon size so this won’t be easy

The hardest to find parts is anything related to the manual transmission. It’s really like looking for a needle in a haystack.

The hardest to find parts is anything related to the manual transmission. It’s really like looking for a needle in a haystack.