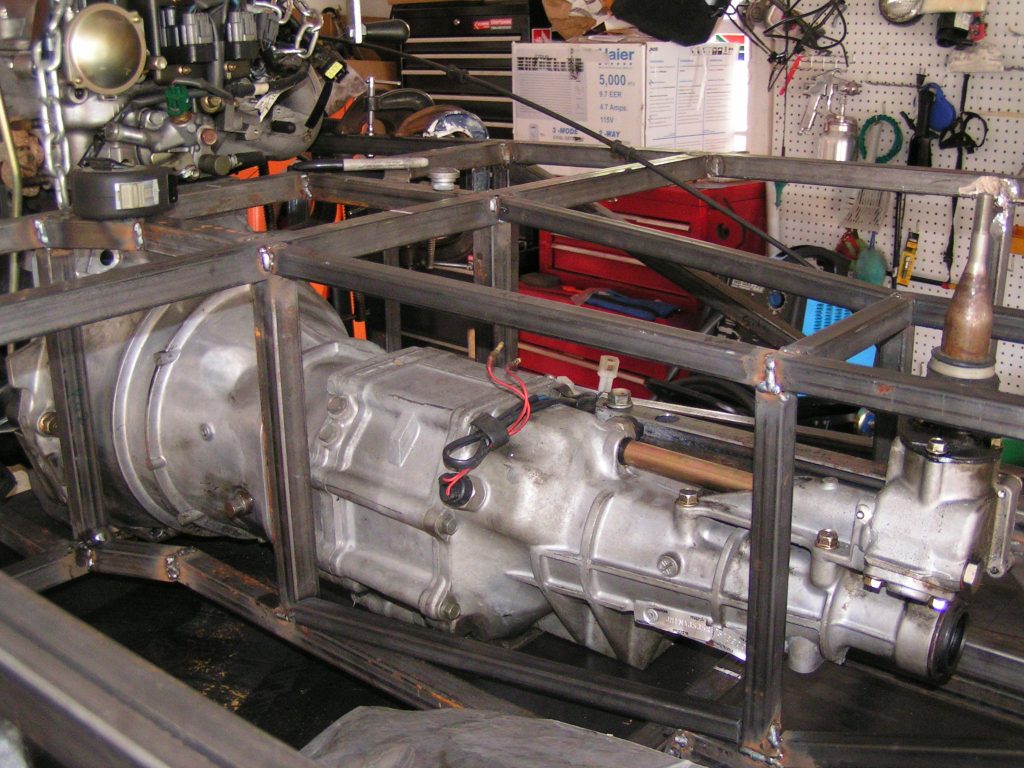

With the car being so low I knew I needed to have some form of protection from other vehicles. While the tall front cage is probably safer I like the look of the low front hoop and the “cocoon” it creates.

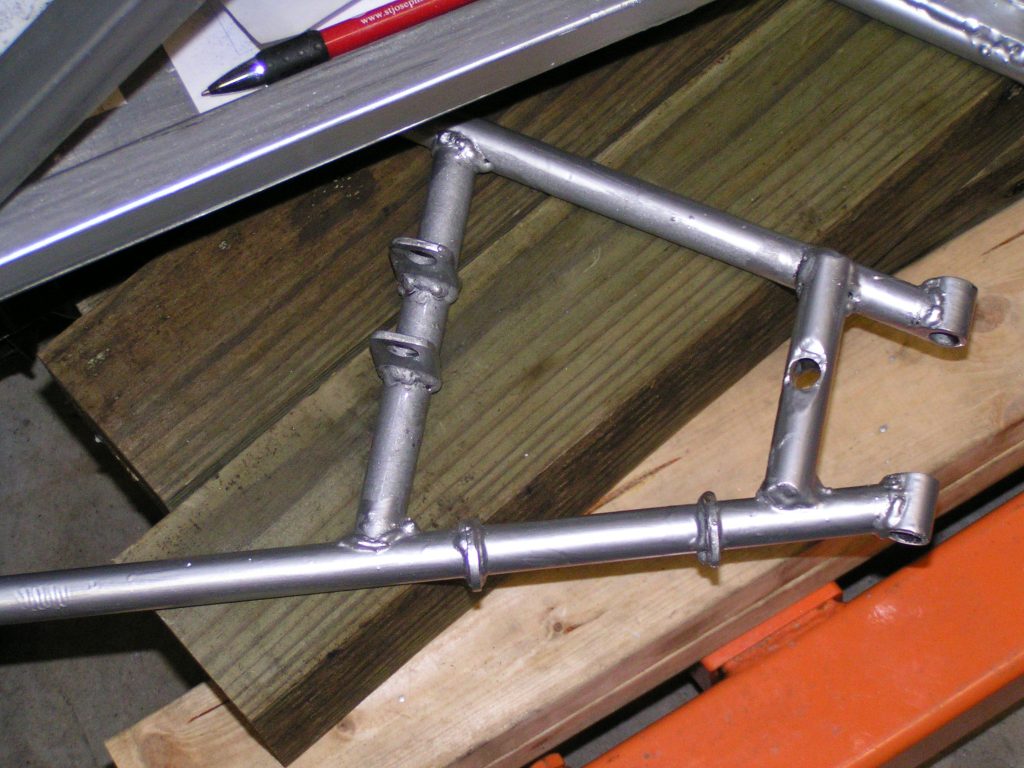

I wanted to have a low front hoop but side protection. There are some NASA cars running this type of cage and I really liked it. The strength it adds to the frame is a huge factor as well. Cage is built to SCCA Spec using 1.75″ DOM Tubing.

The front hoop mirrors the scuttle almost perfectly. The lower sections are attached via two points to the chassis and provides really strong side impact protection.