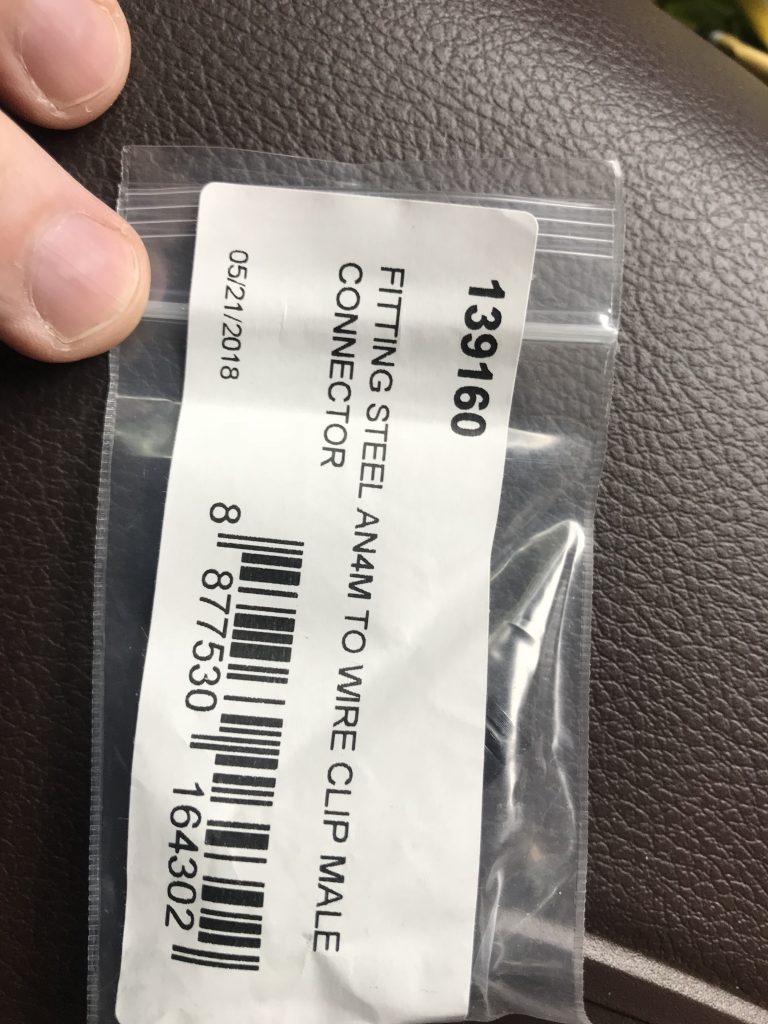

If you own a Camaro or ATS chances are you have the same transmission I am using. The one piece I will be using is the stock throw out bearing. Unfortunately The clutch hose I received was cut and my car actually has a steel braided AN line today. I plan to simply unscrew the -4 fitting that attaches to the miata slave cylinder and thread this piece on. That should be all that is needed to operate the hydraulic clutch for the LTG.

Flywheel pilot bearing hell!

My personal opinion is that Fidanza shouldn’t be allowed to sell parts with sick half assed support . To get a party they recommended I would have to go to Europe or China but online the part is harder to find than a uniform.

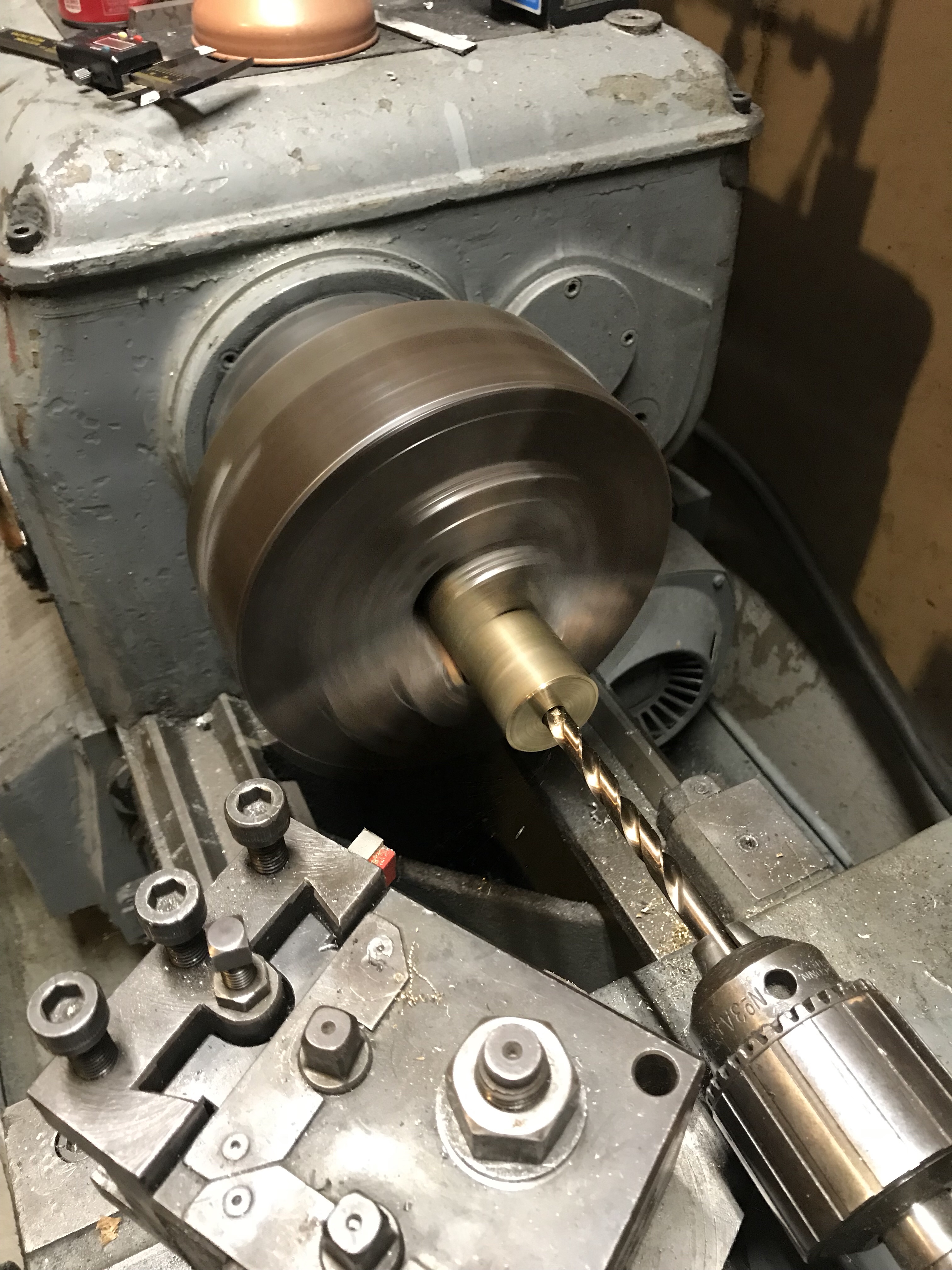

I bought a piece of bronze on what and stayed to machine my own. The dimensions were simple. 16mmID 28mmOD and 26mm in length. It took about an hour to make.

Overall it will get the job done and be fine. That said I am no where near the phase of recommending a fidanza product. Especially after the need for custom bolts!

http://www.exportedafrican.com/wordpress/wp-content/uploads/2018/06/img_8470.mov

http://www.exportedafrican.com/wordpress/wp-content/uploads/2018/06/img_8470.mov

Video showing the Flywheel, Clutch and Pressure Plate

A short video showing the various components. It is a self adjusting pressure plate which was an interesting discovery for the first time!